Weld Procedure Template

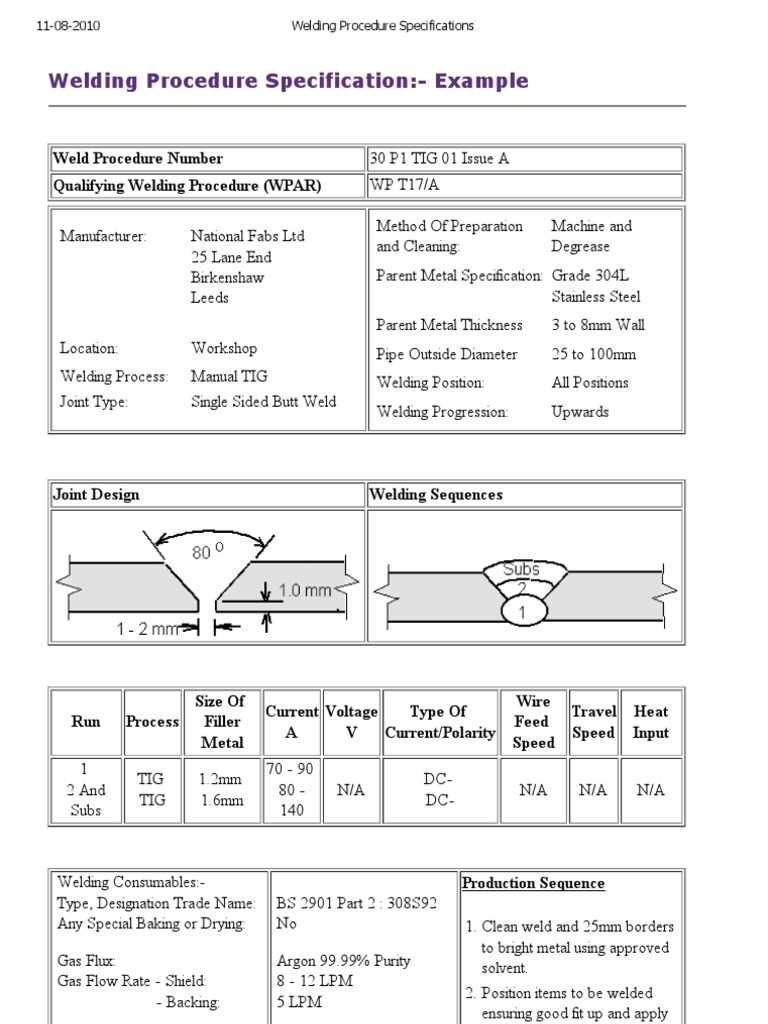

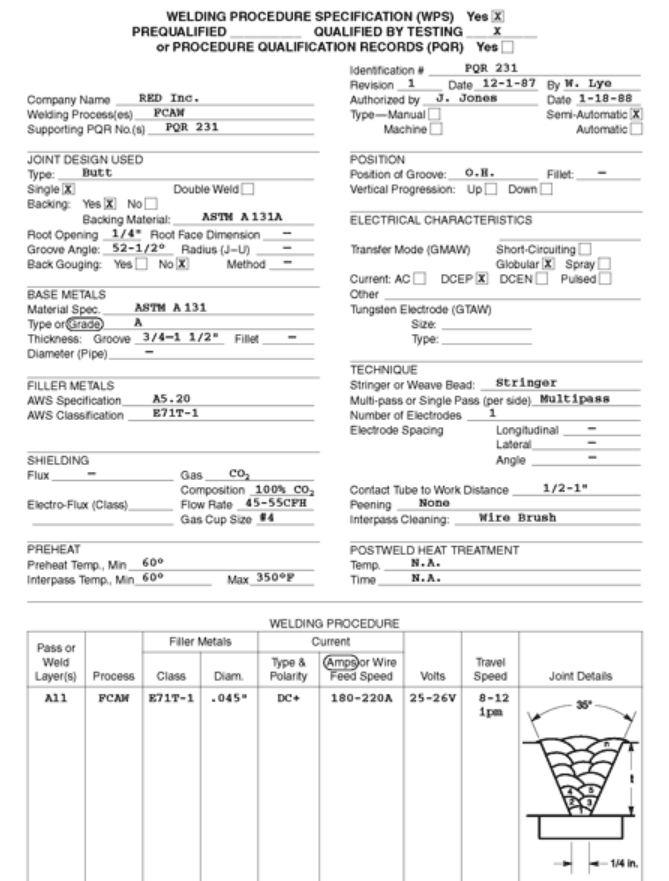

Weld Procedure Template - Sign, fax and printable from pc, ipad, tablet or mobile with pdffiller instantly. Access free downloads of essential aws welding standards and resources. The need for and the temperature of preheat are dependent upon a number of factors such as chemical. You can also download it, export it or print it out. It contains all the necessary parameters viz. Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple process procedures, etc.)] A welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). Up to 40% cash back send welding procedure specification format in word via email, link, or fax. Welding procedure specification (wps) sample (www.weldingandndt.com) date: It specifies the base and filler metals, joint. A welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). You can also download it, export it or print it out. Explore a wide range of welding guidelines and documents to support your welding projects and safety practices. It specifies the base and filler metals, joint. Aws d1.1/d1.1m:2010 annex n 355 welding procedure specification (wps) yes prequalified _____ qualified by testing _____ or procedure qualification records (pqr) yes Up to $50 cash back fill welding procedure specification template, edit online. Edit your weld procedure template. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Up to 40% cash back send welding procedure specification format in word via email, link, or fax. It contains all the necessary parameters viz. Welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual. It contains all the necessary parameters viz. Up to $50 cash back fill welding procedure specification template, edit online. Aws d1.1/d1.1m:2010 annex n 355 welding procedure specification (wps) yes prequalified. Preheat and interpass temperature shall be sufficient to prevent cold cracking. Welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual. Up to 40% cash back send welding procedure specification format in word via email, link, or fax. Explore a. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. A welding procedure specification (wps) is a written document providing. Edit your weld procedure template. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Explore a wide range of welding guidelines and documents to support your welding projects and safety practices. Welding procedure specification (wps) sample (www.weldingandndt.com) date: Sign, fax and printable from pc,. Edit your weld procedure template. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. You can also download it, export it or print it out. Access free downloads of essential aws welding standards and resources. Up to 40% cash back send welding procedure specification. Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple process procedures, etc.)] Up to 40% cash back send welding procedure specification format in word via email, link, or fax. Aws d1.1/d1.1m:2010 annex n 355 welding procedure specification (wps) yes prequalified _____ qualified by testing _____ or procedure qualification records. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Welding procedure specification (wps) sample (www.weldingandndt.com) date: A welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). Preheat and interpass temperature shall be sufficient to prevent cold cracking.. 1.fit up 2.welding*/cleaning 3.visual inspection 4.ndt(rt,ut,pt,mt)**. Preheat and interpass temperature shall be sufficient to prevent cold cracking. Aws d1.1/d1.1m:2010 annex n 355 welding procedure specification (wps) yes prequalified _____ qualified by testing _____ or procedure qualification records (pqr) yes A welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). Welding procedure specification (wps). Explore a wide range of welding guidelines and documents to support your welding projects and safety practices. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Sign, fax and printable from pc, ipad, tablet or mobile with pdffiller instantly. Edit your weld procedure template.. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Preheat and interpass temperature shall be sufficient to prevent cold cracking. A welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). Access free downloads of essential aws welding. A welding procedure specification (wps) sets broad guidelines for the shop and field welding practice of the fabricator for each anticipated combination of essential variables. Edit your weld procedure template. It contains all the necessary parameters viz. 1.fit up 2.welding*/cleaning 3.visual inspection 4.ndt(rt,ut,pt,mt)**. Aws d1.1/d1.1m:2010 annex n 355 welding procedure specification (wps) yes prequalified _____ qualified by testing _____ or procedure qualification records (pqr) yes Up to 40% cash back send welding procedure specification format in word via email, link, or fax. A welding procedure specification (wps) is a written document providing direction to the welder (or welding operator). Explore a wide range of welding guidelines and documents to support your welding projects and safety practices. Sign, fax and printable from pc, ipad, tablet or mobile with pdffiller instantly. Welding procedure specification (wps) sample (www.weldingandndt.com) date: Sketches may be attached to illustrate joint design, weld layers, and bead sequence (e.g., for notch toughness procedures, for multiple process procedures, etc.)] Preheat and interpass temperature shall be sufficient to prevent cold cracking. You can also download it, export it or print it out. The need for and the temperature of preheat are dependent upon a number of factors such as chemical. Welding procedure pass or filler metals current weld type & amps or wire travel layers process class diam polarity feed speed* volts* speed* joint details *** * n/a for manual.Welding Procedure Specification Template Welding Electric Heating

Guide to Writing a Welding Procedure Specification December 2015

Welding Procedure Specification (ASME Section IX 2019 Edition

Welding Procedure Specification Template

Welding Procedure Specification Template Fill Online, Printable

Weld Procedure Template

Welding Procedure Specification Template Printable Templates

Welding procedure specification template Fill out & sign online DocHub

What is Welding Procedure Specification (WPS)?

The basics of preparing a welding documentation

A Welding Procedure Specification (Wps) Sets Broad Guidelines For The Shop And Field Welding Practice Of The Fabricator For Each Anticipated Combination Of Essential Variables.

It Specifies The Base And Filler Metals, Joint.

Up To $50 Cash Back Fill Welding Procedure Specification Template, Edit Online.

Access Free Downloads Of Essential Aws Welding Standards And Resources.

Related Post: