Silica Plan Template

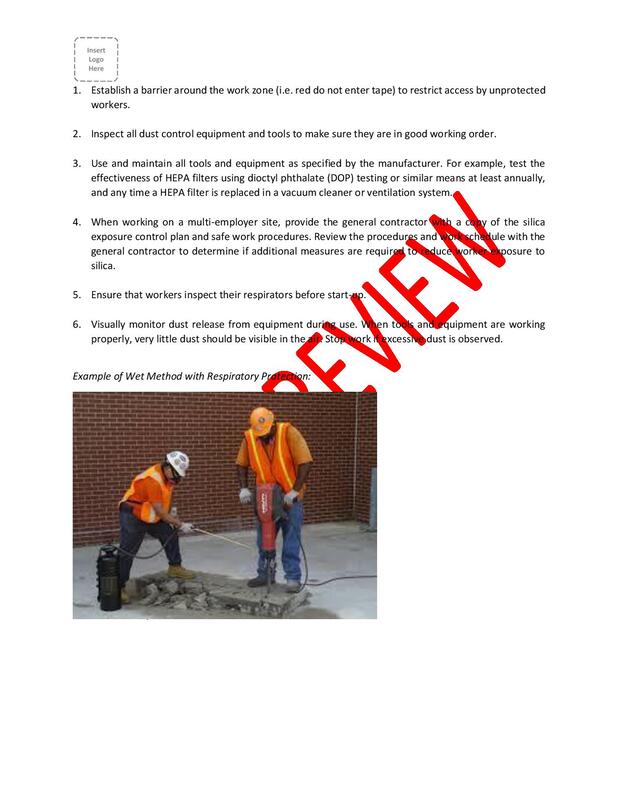

Silica Plan Template - Operate and maintain tool in accordance with manufacturer’s instructions to minimize. Restricting access to work areas and regulated areas, when necessary, minimizes the number of employees exposed to respirable crystalline silica and their level of exposure, including. This template will help you to document details of any processing of a crystalline silica substance (css) that is high risk and the control measures used to manage the risks of exposure to. Keep a copy of this plan at the jobsite. This silica dust management plan contains policy and procedure to document an organisation's aim to protect the safety of its workers by implementing risk management strategies for. Cal osha developed this model plan to assist employers engaged in construction activities, as defined by section 1502(a), with creating their silica exposure control plan. We’ll offer ideas, and at the end send you a plan template which you can use to develop your own silica dust control plan. 1.1 to protect our workers and ensure they do not come into contact with silica in excess of the permissible exposure limit (pel) of 50. The data must reflect workplace. Describe the specific tasks that will be performed that involve exposure to respirable crystalline silica: Use saw equipped with integrated water delivery system that continuously feeds water to the blade. Operate and maintain tool in accordance with manufacturer’s instructions to minimize. Equipment (check all that apply): Measure workers’ exposure to silica and independent ly decide which dust controls work best to limit exposures below the permissible exposure limit (pel) in their workplaces. Establish and maintain the university silica exposure control plan. The data must reflect workplace. Restricting access to work areas and regulated areas, when necessary, minimizes the number of employees exposed to respirable crystalline silica and their level of exposure, including. This silica dust management plan contains policy and procedure to document an organisation's aim to protect the safety of its workers by implementing risk management strategies for. Worker exposure is primarily limited to inhalation. This silica exposure control plan (ecp) template has been developed for the upstream oil and gas industry to assist in managing silica exposures. 1.1 to protect our workers and ensure they do not come into contact with silica in excess of the permissible exposure limit (pel) of 50. Provide this plan of action to. The data must reflect workplace. Use saw equipped with integrated water delivery system that continuously feeds water to the blade. A crystalline silica exposure control plan (word) is required. The silica exposure control plan applies to all ncsu employees who are exposed to respirable crystalline silica (rcs) at or above permissible limits, as determined by environmental health. Substance, demonstrating employee exposure to respirable crystalline silica associated with a product or material or specific process, task, or activity. This silica dust management plan contains policy and procedure to document an. 1.1 to protect our workers and ensure they do not come into contact with silica in excess of the permissible exposure limit (pel) of 50. Use saw equipped with integrated water delivery system that continuously feeds water to the blade. A crystalline silica exposure control plan (word) is required when respirable crystalline silica exposure is assumed or known to be. (same conditions, equipment, process, controls, material silica %, environmental.) review and update this plan annually. We’ll offer ideas, and at the end send you a plan template which you can use to develop your own silica dust control plan. Here are the seven modules you can expect when you register. The silica exposure control plan applies to all ncsu employees. Substance, demonstrating employee exposure to respirable crystalline silica associated with a product or material or specific process, task, or activity. Yale university’s written crystalline silica exposure control plan is designed to prevent health effects from respirable crystalline silica exposures. When silica containing materials are processed, disturbed, moved, or otherwise handled, silica exposure can occur. Keep a copy of this plan. This silica exposure control plan (ecp) template has been developed for the upstream oil and gas industry to assist in managing silica exposures. Restricting access to work areas and regulated areas, when necessary, minimizes the number of employees exposed to respirable crystalline silica and their level of exposure, including. 1.1 to protect our workers and ensure they do not come. Worker exposure is primarily limited to inhalation. (same conditions, equipment, process, controls, material silica %, environmental.) review and update this plan annually. Use saw equipped with integrated water delivery system that continuously feeds water to the blade. This silica dust management plan contains policy and procedure to document an organisation's aim to protect the safety of its workers by implementing. Measure workers’ exposure to silica and independent ly decide which dust controls work best to limit exposures below the permissible exposure limit (pel) in their workplaces. This silica dust management plan contains policy and procedure to document an organisation's aim to protect the safety of its workers by implementing risk management strategies for. Cal osha developed this model plan to. Silica exposure control plan 1. Use saw equipped with integrated water delivery system that continuously feeds water to the blade. Silica is an emerging exposure concern in oil Substance, demonstrating employee exposure to respirable crystalline silica associated with a product or material or specific process, task, or activity. We’ll offer ideas, and at the end send you a plan template. (same conditions, equipment, process, controls, material silica %, environmental.) review and update this plan annually. We’ll offer ideas, and at the end send you a plan template which you can use to develop your own silica dust control plan. Silica is an emerging exposure concern in oil Substance, demonstrating employee exposure to respirable crystalline silica associated with a product or. Provide this plan of action to. 1.1 to protect our workers and ensure they do not come into contact with silica in excess of the permissible exposure limit (pel) of 50. When silica containing materials are processed, disturbed, moved, or otherwise handled, silica exposure can occur. Perform air monitoring for virginia tech employees to evaluate silica exposures, and provide technical assistance with. Restricting access to work areas and regulated areas, when necessary, minimizes the number of employees exposed to respirable crystalline silica and their level of exposure, including. Measure workers’ exposure to silica and independent ly decide which dust controls work best to limit exposures below the permissible exposure limit (pel) in their workplaces. The silica exposure control plan applies to all ncsu employees who are exposed to respirable crystalline silica (rcs) at or above permissible limits, as determined by environmental health. This silica dust management plan contains policy and procedure to document an organisation's aim to protect the safety of its workers by implementing risk management strategies for. Here are the seven modules you can expect when you register. Substance, demonstrating employee exposure to respirable crystalline silica associated with a product or material or specific process, task, or activity. We’ll offer ideas, and at the end send you a plan template which you can use to develop your own silica dust control plan. A crystalline silica exposure control plan (word) is required when respirable crystalline silica exposure is assumed or known to be at or above 25 μg/m3twa8e of. Cal osha developed this model plan to assist employers engaged in construction activities, as defined by section 1502(a), with creating their silica exposure control plan. Cal/osha developed this model plan to assist employers with creating their own silica exposure control plan. (same conditions, equipment, process, controls, material silica %, environmental.) review and update this plan annually. Operate and maintain tool in accordance with manufacturer’s instructions to minimize.Silica Exposure Plan Template Master of Documents

Silica ECP Template

Silica Safety Plan Template

Osha Silica Exposure Control Plan Template

Silica Safety Plan Template

Plan The Job, Inc. Crystalline Silica Control Plan

40 Silica Exposure Control Plan Template Hamiltonplastering

40 Silica Exposure Control Plan Template Hamiltonplastering

40 Silica Exposure Control Plan Template Hamiltonplastering

40 Silica Exposure Control Plan Template Hamiltonplastering

Use Saw Equipped With Integrated Water Delivery System That Continuously Feeds Water To The Blade.

The Data Must Reflect Workplace.

Equipment (Check All That Apply):

Keep A Copy Of This Plan At The Jobsite.

Related Post: