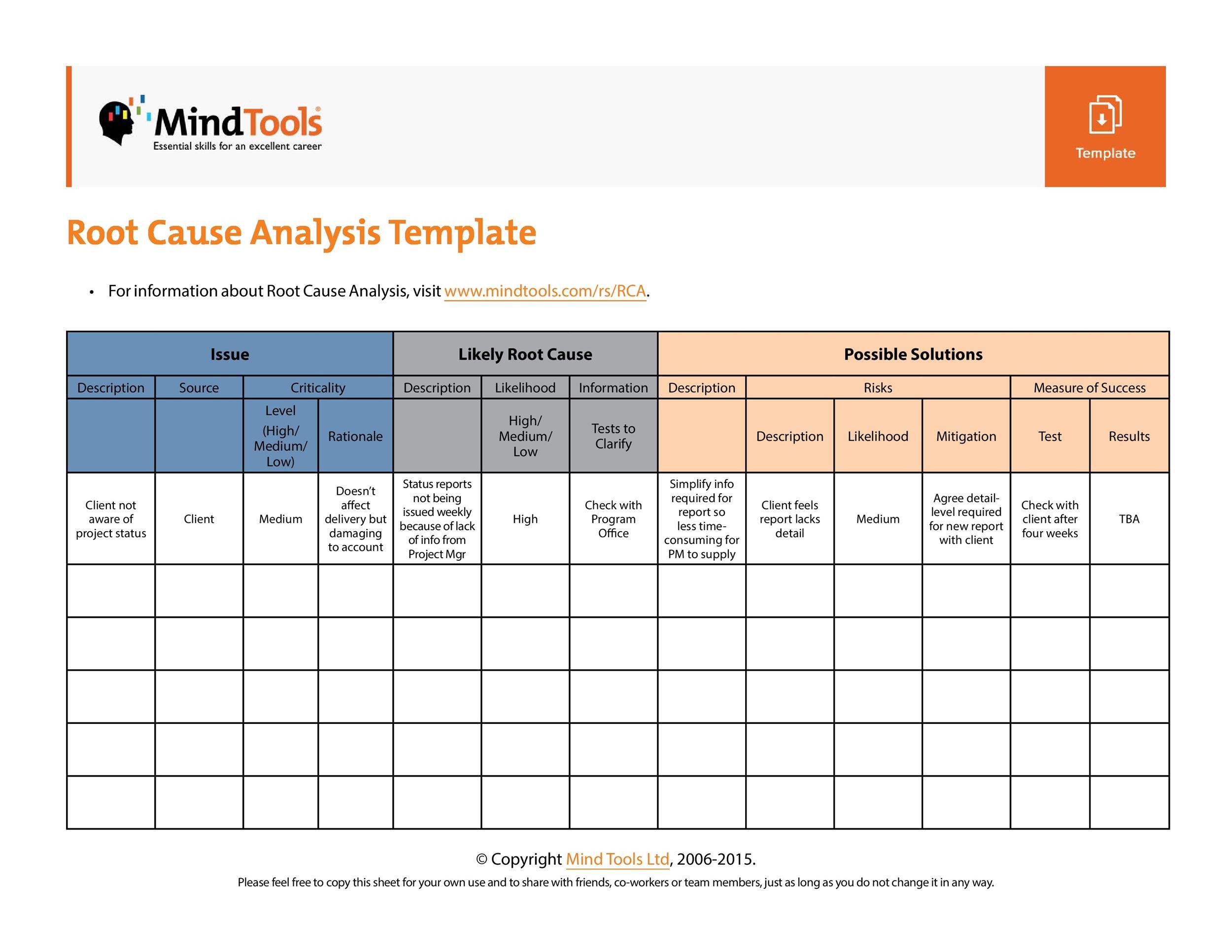

Root Cause Template

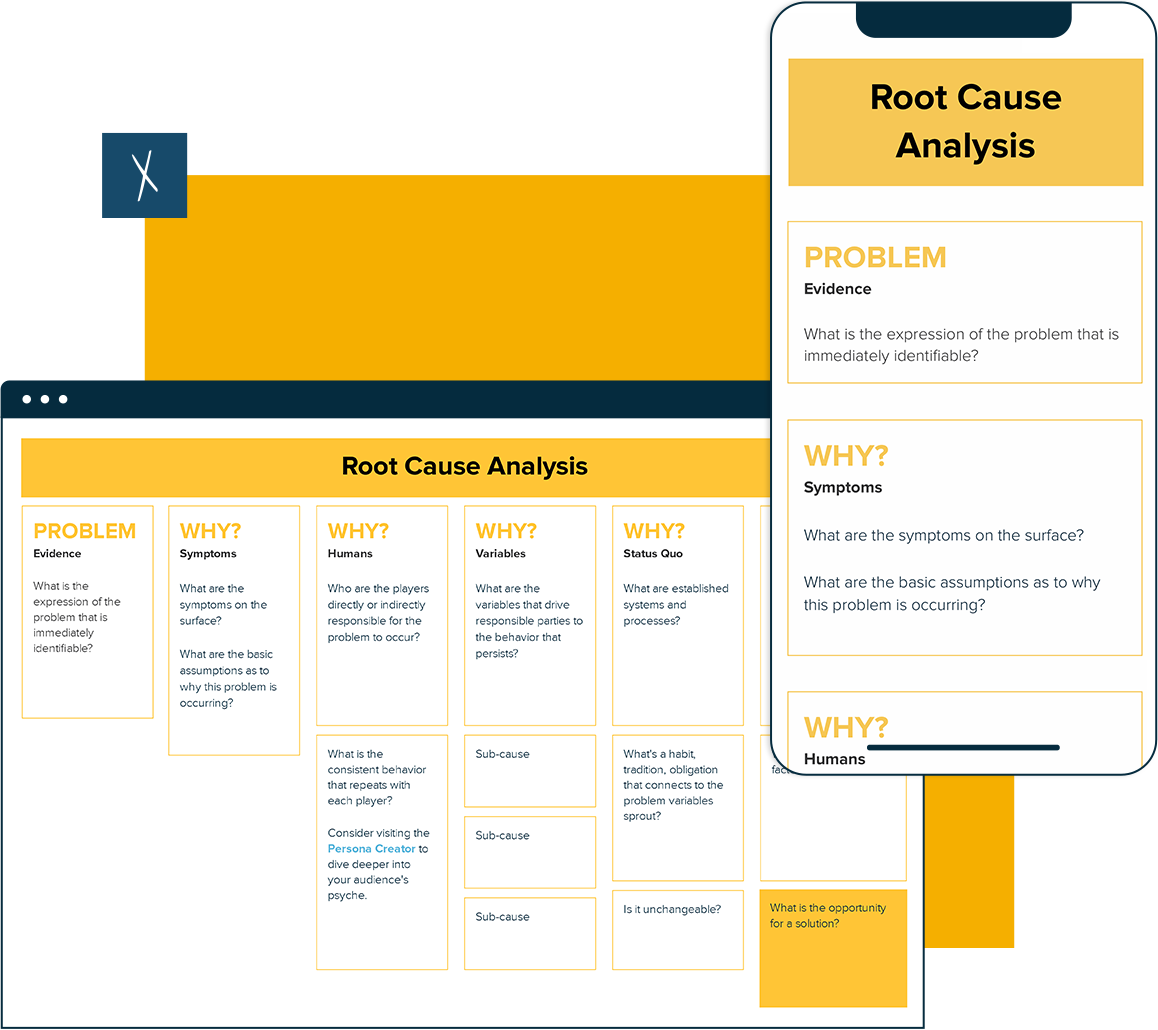

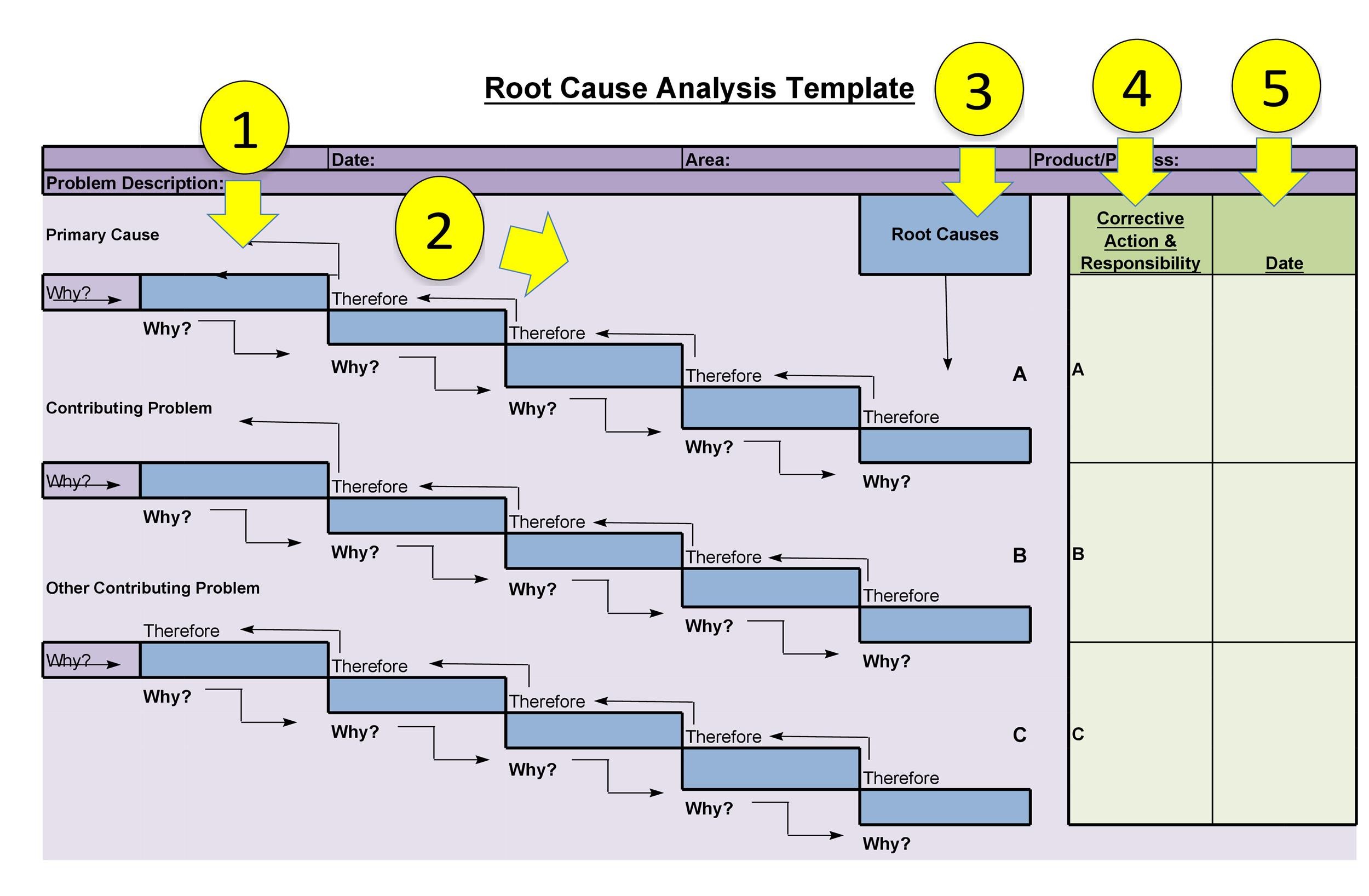

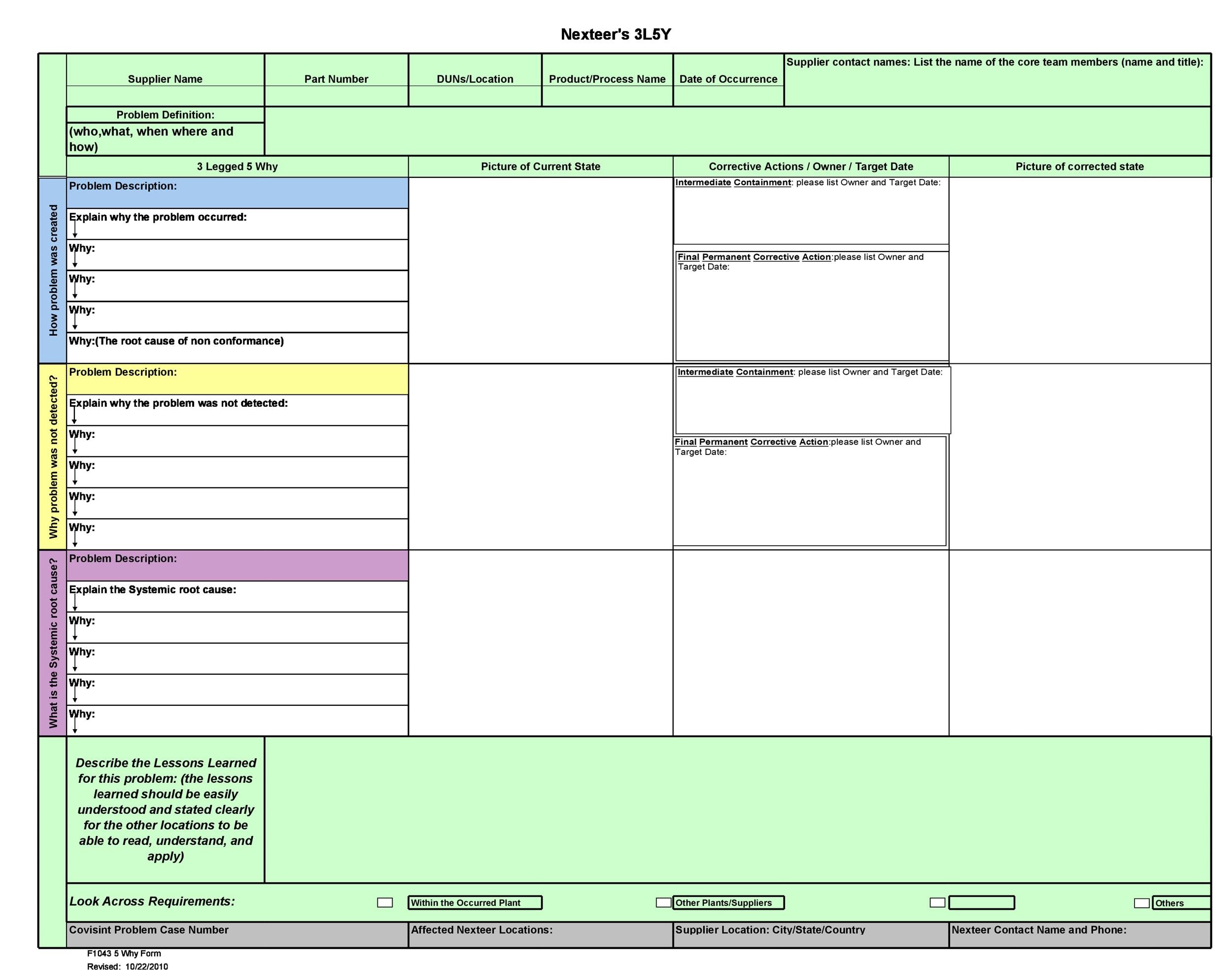

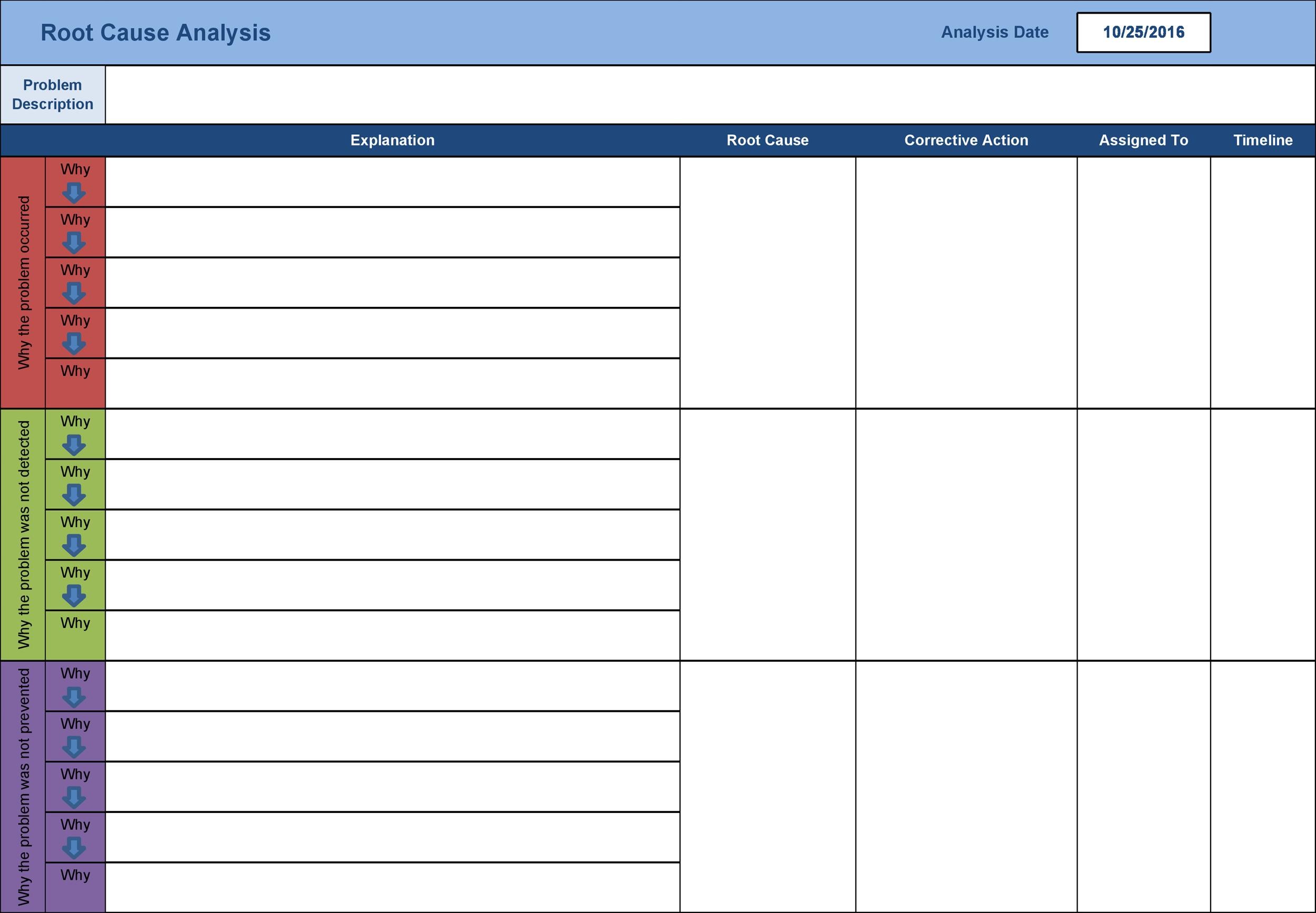

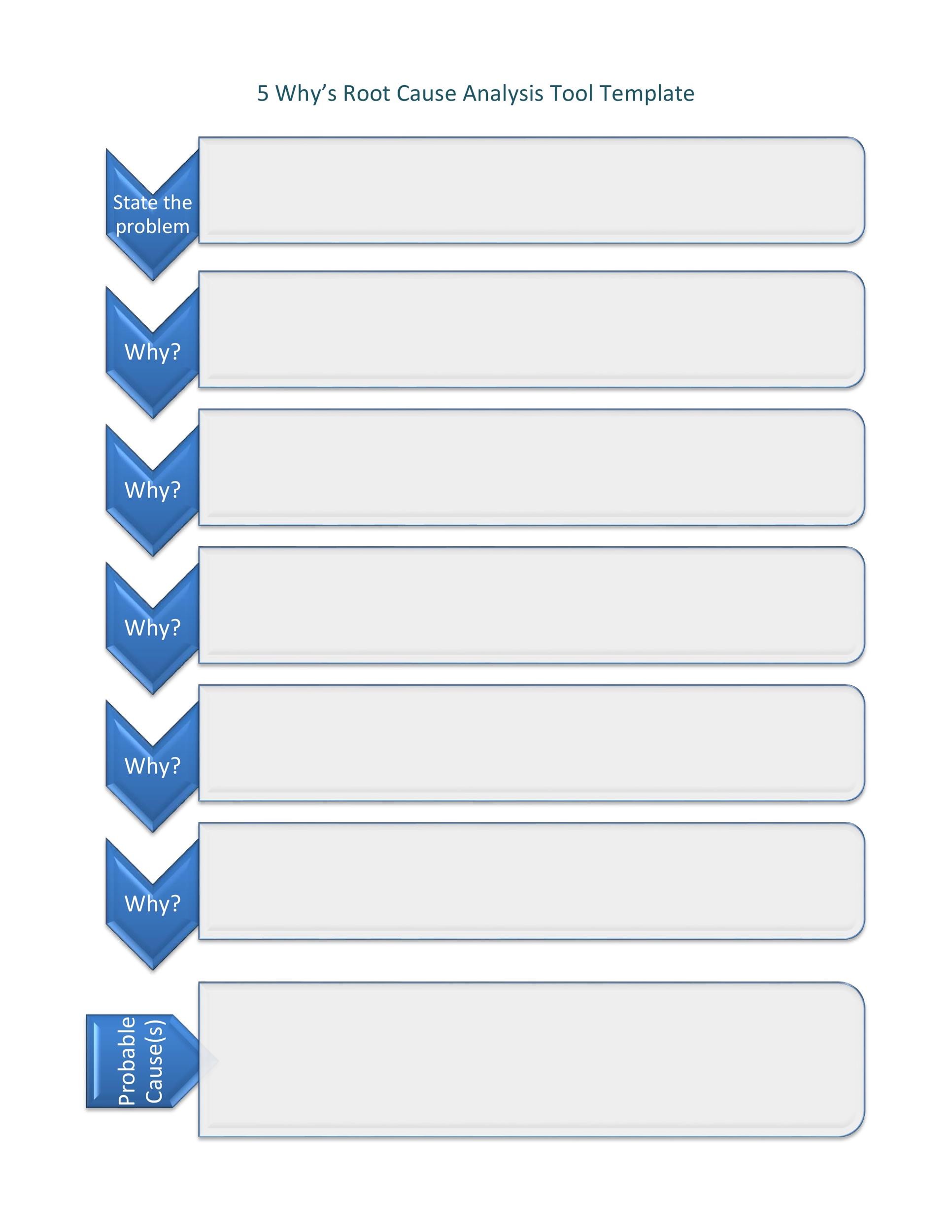

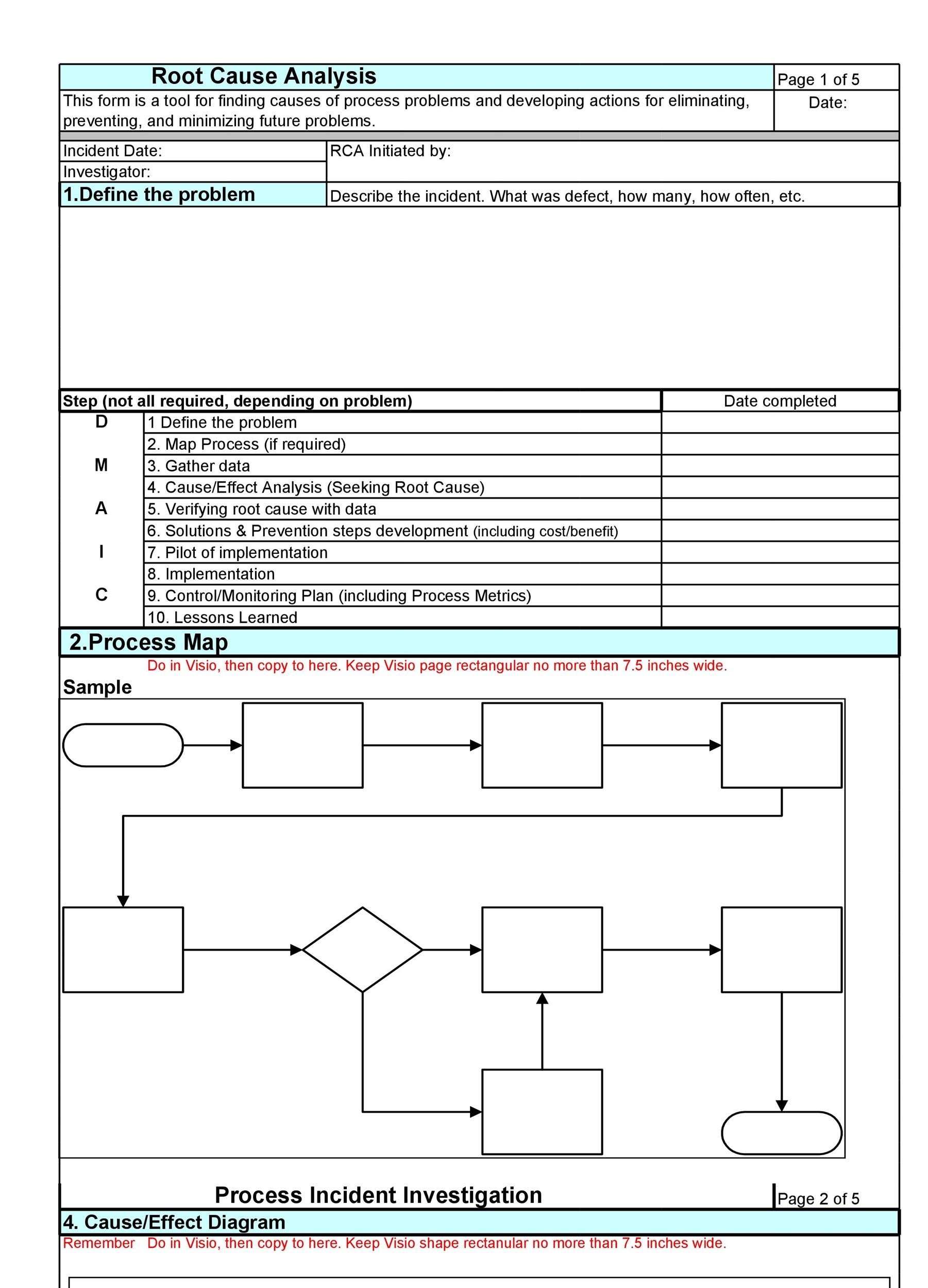

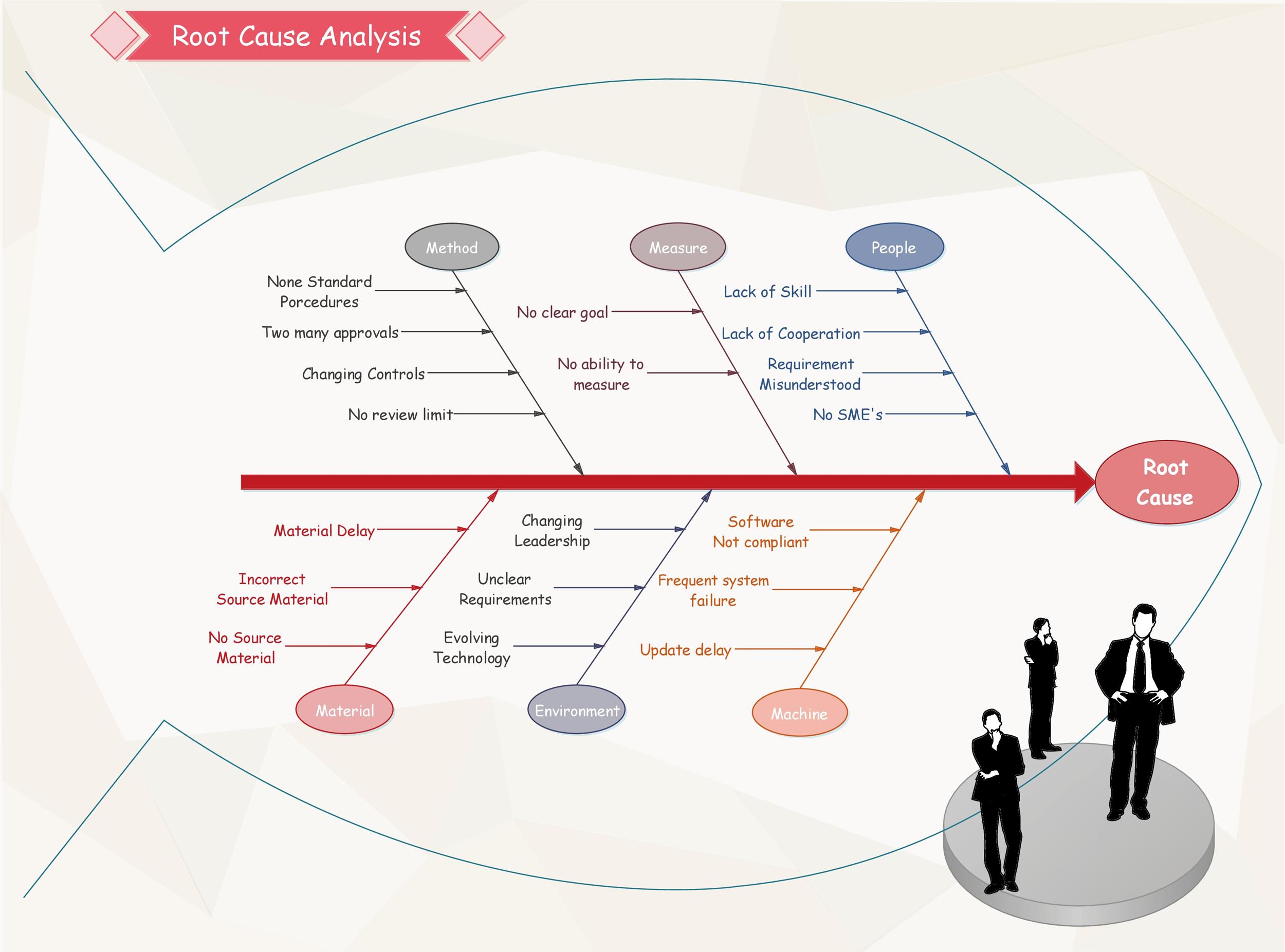

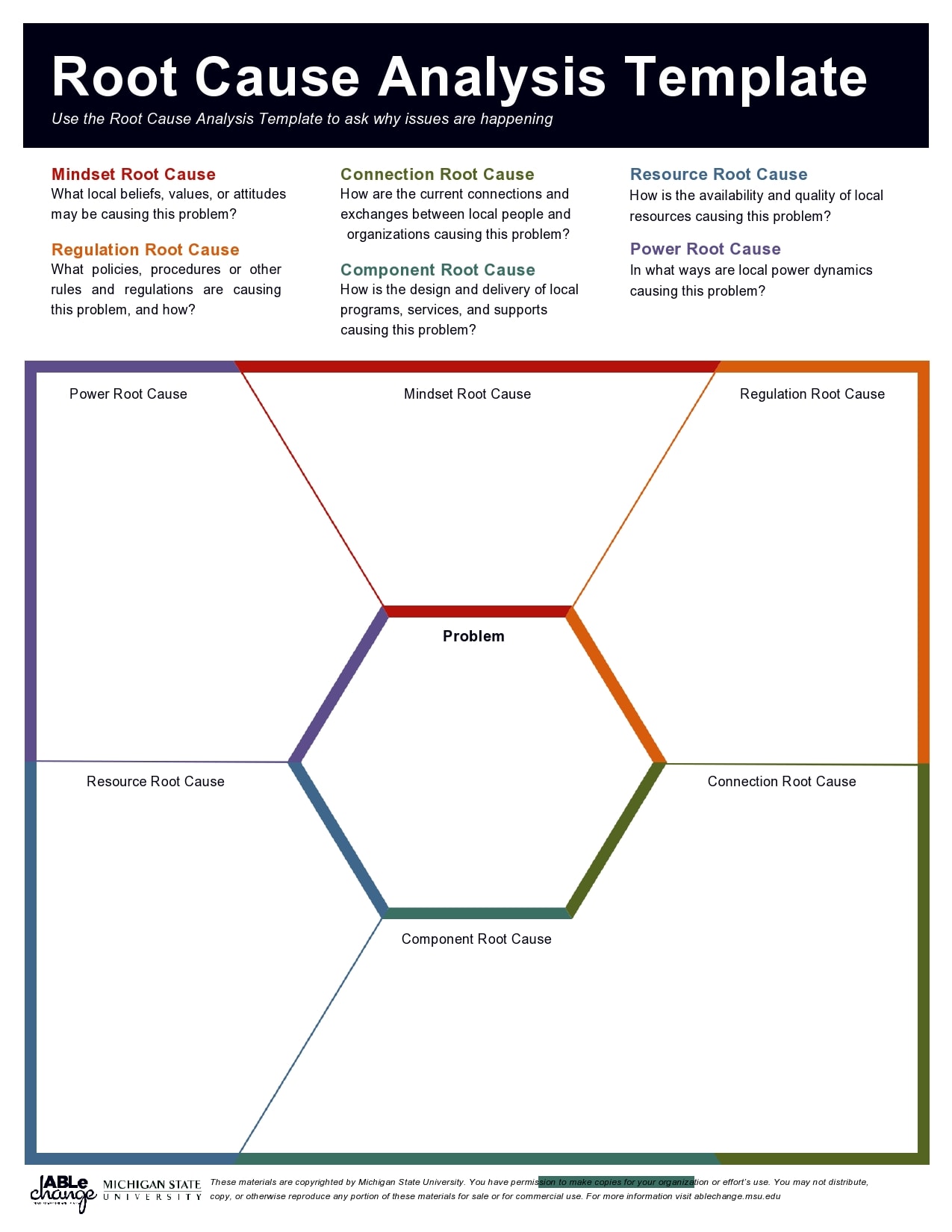

Root Cause Template - Define the problem corrective action to take. Characterize the gap between voc and vop confirm root cause with analytics with analytics apply resolution describe and gage the gap complete cause/effect investigation to classify root causes manage and maintain process improvement If the final why has no controllable solution, return to the previous why. root cause. Why is this a problem? 5 why’s template define the problem why is this a problem? Download a dmaic root cause analysis report template for excel | microsoft word | adobe pdf. Use this dmaic report template during the analysis phase to identify, verify, and document the root. Use root cause analysis techniques such as five whys to identify these. Primary cause why is it happening? 5 whys root cause analysis template. If the final why has no controllable solution, return to the previous why. root cause. Use root cause analysis techniques such as five whys to identify these. D4 identify the root cause list all possible root causes for the problems. Product/process department completed by date. The template accommodates a broad range of ideas, ensuring that no potential cause is overlooked. Characterize the gap between voc and vop confirm root cause with analytics with analytics apply resolution describe and gage the gap complete cause/effect investigation to classify root causes manage and maintain process improvement 5 whys root cause analysis template. See dmaic problem solving (indicating the importance of finding root causes) example below: Primary cause why is it happening? With eight distinct bones, this diagram allows for a thorough root cause analysis. Characterize the gap between voc and vop confirm root cause with analytics with analytics apply resolution describe and gage the gap complete cause/effect investigation to classify root causes manage and maintain process improvement With eight distinct bones, this diagram allows for a thorough root cause analysis. 5 why’s template define the problem why is this a problem? If the final. Product/process department completed by date. It includes a detailed problem outline, a timeline, a “why” question analysis, diagrams to help illustrate the process, sections for proposing and evaluating possible solutions, and a. Define the problem corrective action to take. Find fishbone templates for manufacturing, marketing, 5 ws analysis, and more. See dmaic problem solving (indicating the importance of finding root. Download a dmaic root cause analysis report template for excel | microsoft word | adobe pdf. Primary cause why is it happening? Define the problem corrective action to take. Find fishbone templates for manufacturing, marketing, 5 ws analysis, and more. Use root cause analysis techniques such as five whys to identify these. Find fishbone templates for manufacturing, marketing, 5 ws analysis, and more. Product/process department completed by date. If the final why has no controllable solution, return to the previous why. 5 corrective action to take corrective action party responsible date. Use root cause analysis techniques such as five whys to identify these. See dmaic problem solving (indicating the importance of finding. The itil problem record template guides you through the data most commonly collected when an it problem occurs, including root cause, associated incidents, and corrective actions. Characterize the gap between voc and vop confirm root cause with analytics with analytics apply resolution describe and gage the gap complete cause/effect investigation to classify root causes manage and maintain process improvement Why. On this page, you’ll find an ishikawa diagram template for root cause analysis, a timeline fishbone template, a medical fishbone diagram template, and many others, including for manufacturing and service industries. It includes a detailed problem outline, a timeline, a “why” question analysis, diagrams to help illustrate the process, sections for proposing and evaluating possible solutions, and a. Use root. Product/process department completed by date. D4 identify the root cause list all possible root causes for the problems. The template accommodates a broad range of ideas, ensuring that no potential cause is overlooked. With eight distinct bones, this diagram allows for a thorough root cause analysis. Define the problem corrective action to take. If the final why has no controllable solution, return to the previous why. 5 corrective action to take corrective action party responsible date. Define the problem corrective action to take. The template accommodates a broad range of ideas, ensuring that no potential cause is overlooked. With eight distinct bones, this diagram allows for a thorough root cause analysis. Primary cause. If the final why has no controllable solution, return to the previous why. 5 corrective action to take corrective action party responsible date. Primary cause why is it happening? Characterize the gap between voc and vop confirm root cause with analytics with analytics apply resolution describe and gage the gap complete cause/effect investigation to classify root causes manage and maintain. 5 why’s template define the problem why is this a problem? The template accommodates a broad range of ideas, ensuring that no potential cause is overlooked. Product/process department completed by date. If the final why has no controllable solution, return to the previous why. root cause. This cause mapping template combines elements of the root cause analysis template, the six. If the final why has no controllable solution, return to the previous why. root cause. When to use this template: The template accommodates a broad range of ideas, ensuring that no potential cause is overlooked. 5 why’s template define the problem why is this a problem? D4 identify the root cause list all possible root causes for the problems. On this page, you’ll find an ishikawa diagram template for root cause analysis, a timeline fishbone template, a medical fishbone diagram template, and many others, including for manufacturing and service industries. If the final why has no controllable solution, return to the previous why. 5 corrective action to take corrective action party responsible date. Product/process department completed by date. Characterize the gap between voc and vop confirm root cause with analytics with analytics apply resolution describe and gage the gap complete cause/effect investigation to classify root causes manage and maintain process improvement This cause mapping template combines elements of the root cause analysis template, the six sigma dmaic template, and the 5 whys root cause analysis template. Download free excel fishbone diagram templates for root cause analysis. Why is this a problem? Use root cause analysis techniques such as five whys to identify these. Primary cause why is it happening? Download a dmaic root cause analysis report template for excel | microsoft word | adobe pdf. With eight distinct bones, this diagram allows for a thorough root cause analysis.Root Cause Analysis Template and Examples Xtensio

What Is Root Cause Analysis Templates And Examples NBKomputer

7 free Root Cause Analysis templates (& how to use them)

40+ Effective Root Cause Analysis Templates, Forms & Examples

40+ Effective Root Cause Analysis Templates, Forms & Examples

40+ Effective Root Cause Analysis Templates, Forms & Examples

40+ Effective Root Cause Analysis Templates, Forms & Examples

40+ Effective Root Cause Analysis Templates, Forms & Examples

Sample Root Cause Analysis Template Printable Templates Free

40+ Effective Root Cause Analysis Templates, Forms & Examples

Define The Problem Corrective Action To Take.

See Dmaic Problem Solving (Indicating The Importance Of Finding Root Causes) Example Below:

It Includes A Detailed Problem Outline, A Timeline, A “Why” Question Analysis, Diagrams To Help Illustrate The Process, Sections For Proposing And Evaluating Possible Solutions, And A.

Use This Dmaic Report Template During The Analysis Phase To Identify, Verify, And Document The Root.

Related Post: