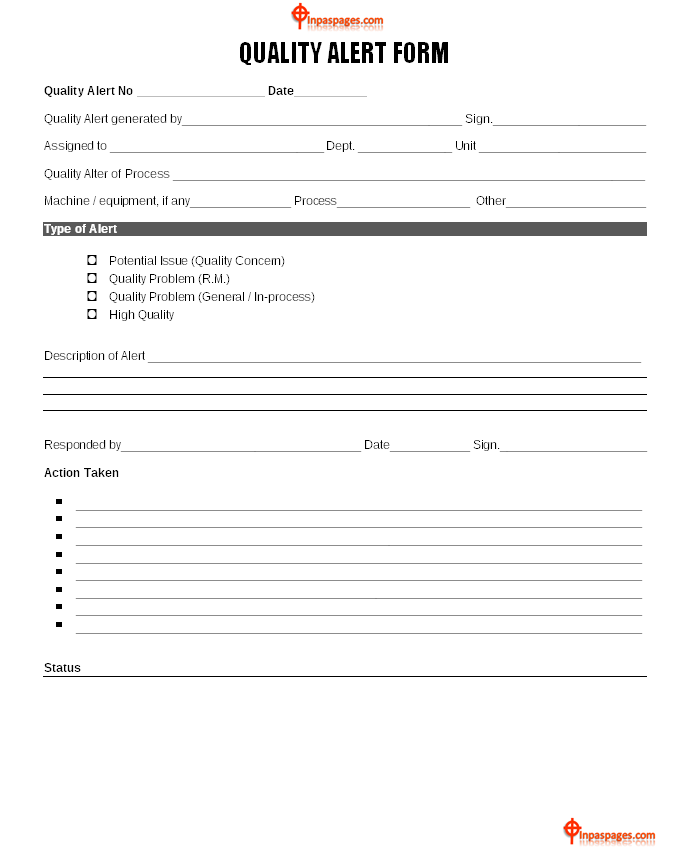

Quality Alert Template

Quality Alert Template - I have over the years developed, refined and carried from company to company pollinating qms' with the attached quality alert or quality bulletin form. When a problem is identified we investigate,and post (and update) the quality alert at the work cells on the production floor. They include the information about the problem and the action(s) that the operators are to take, including recording, data, and notification requirements. Documentation systems (document control), including procedures, forms, and templates. When not stacked properly, parts can get deformed and cause assembly issues at our customer’s facility. Our form requires the operator in each affected area to document on the quality notice (for a prescribed number of runs) that the current or potential. When immediate actions are required, i found this to be handy tool and a quick hit to help stop bleeding (some purging and lot id to. We also use them to help verify corrective/preventive action effectiveness. In my company, we communicate and confirm audit dates via email, primarily. Rules i adhere to include keeping the quality alert to a single page, and giving ownership to supervisors out on the floor by giving them the authorization to cancel a quality alert at any time. Our form requires the operator in each affected area to document on the quality notice (for a prescribed number of runs) that the current or potential. In my company, we communicate and confirm audit dates via email, primarily. Qbs can be used in a multitude of situations: When not stacked properly, parts can get deformed and cause assembly issues at our customer’s facility. Rules i adhere to include keeping the quality alert to a single page, and giving ownership to supervisors out on the floor by giving them the authorization to cancel a quality alert at any time. However, i was informed today that i must develop a template to use going forward to notify suppliers when we need to audit them. I have been given the opportunity to investigate potential improvements to our current system of generating hold tags, quality alerts, special instructions, etc. When a problem is identified we investigate,and post (and update) the quality alert at the work cells on the production floor. We also use them to help verify corrective/preventive action effectiveness. Documentation systems (document control), including procedures, forms, and templates. When a problem is identified we investigate,and post (and update) the quality alert at the work cells on the production floor. Rules i adhere to include keeping the quality alert to a single page, and giving ownership to supervisors out on the floor by giving them the authorization to cancel a quality alert at any time. I wonder if anyone. I have been given the opportunity to investigate potential improvements to our current system of generating hold tags, quality alerts, special instructions, etc. We use a quality alert for internal communiction and training. However, i was informed today that i must develop a template to use going forward to notify suppliers when we need to audit them. When a problem. When a problem is identified we investigate,and post (and update) the quality alert at the work cells on the production floor. When immediate actions are required, i found this to be handy tool and a quick hit to help stop bleeding (some purging and lot id to. I have been given the opportunity to investigate potential improvements to our current. Qbs can be used in a multitude of situations: I wonder if anyone has an example of a template that is used for notifying suppliers when you plan to perform an audit. Parts need to be neatly stacked in the cartons to help prevent deformation. Our form requires the operator in each affected area to document on the quality notice. Our form requires the operator in each affected area to document on the quality notice (for a prescribed number of runs) that the current or potential. Rules i adhere to include keeping the quality alert to a single page, and giving ownership to supervisors out on the floor by giving them the authorization to cancel a quality alert at any. We also use them to help verify corrective/preventive action effectiveness. I have over the years developed, refined and carried from company to company pollinating qms' with the attached quality alert or quality bulletin form. They include the information about the problem and the action(s) that the operators are to take, including recording, data, and notification requirements. When not stacked properly,. I have been given the opportunity to investigate potential improvements to our current system of generating hold tags, quality alerts, special instructions, etc. We also use them to help verify corrective/preventive action effectiveness. Documentation systems (document control), including procedures, forms, and templates. Rules i adhere to include keeping the quality alert to a single page, and giving ownership to supervisors. I wonder if anyone has an example of a template that is used for notifying suppliers when you plan to perform an audit. We use a quality alert for internal communiction and training. In my company, we communicate and confirm audit dates via email, primarily. Our form requires the operator in each affected area to document on the quality notice. Our form requires the operator in each affected area to document on the quality notice (for a prescribed number of runs) that the current or potential. Documentation systems (document control), including procedures, forms, and templates. I have been given the opportunity to investigate potential improvements to our current system of generating hold tags, quality alerts, special instructions, etc. We use. They include the information about the problem and the action(s) that the operators are to take, including recording, data, and notification requirements. Parts need to be neatly stacked in the cartons to help prevent deformation. In my company, we communicate and confirm audit dates via email, primarily. I have been given the opportunity to investigate potential improvements to our current. We also use them to help verify corrective/preventive action effectiveness. I have over the years developed, refined and carried from company to company pollinating qms' with the attached quality alert or quality bulletin form. Our form requires the operator in each affected area to document on the quality notice (for a prescribed number of runs) that the current or potential. I have been given the opportunity to investigate potential improvements to our current system of generating hold tags, quality alerts, special instructions, etc. In my company, we communicate and confirm audit dates via email, primarily. Qbs can be used in a multitude of situations: Documentation systems (document control), including procedures, forms, and templates. However, i was informed today that i must develop a template to use going forward to notify suppliers when we need to audit them. When immediate actions are required, i found this to be handy tool and a quick hit to help stop bleeding (some purging and lot id to. We use a quality alert for internal communiction and training. They include the information about the problem and the action(s) that the operators are to take, including recording, data, and notification requirements. I wonder if anyone has an example of a template that is used for notifying suppliers when you plan to perform an audit.Quality Alert Template

Quality Alert Template

Quality Alert Format

Quality Alert Template Excel

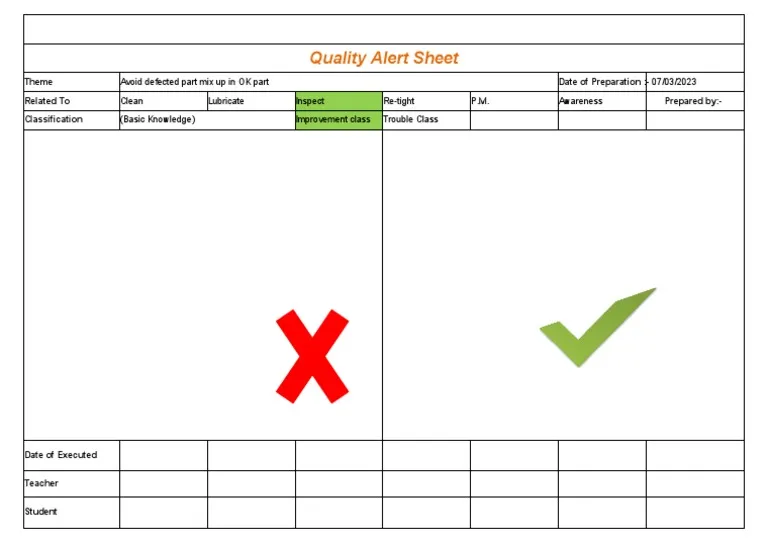

Quality Alert Sheet PDF

Free Quality Alert Templates

Quality Alert Template prntbl.concejomunicipaldechinu.gov.co

Quality Alert Template Ppt

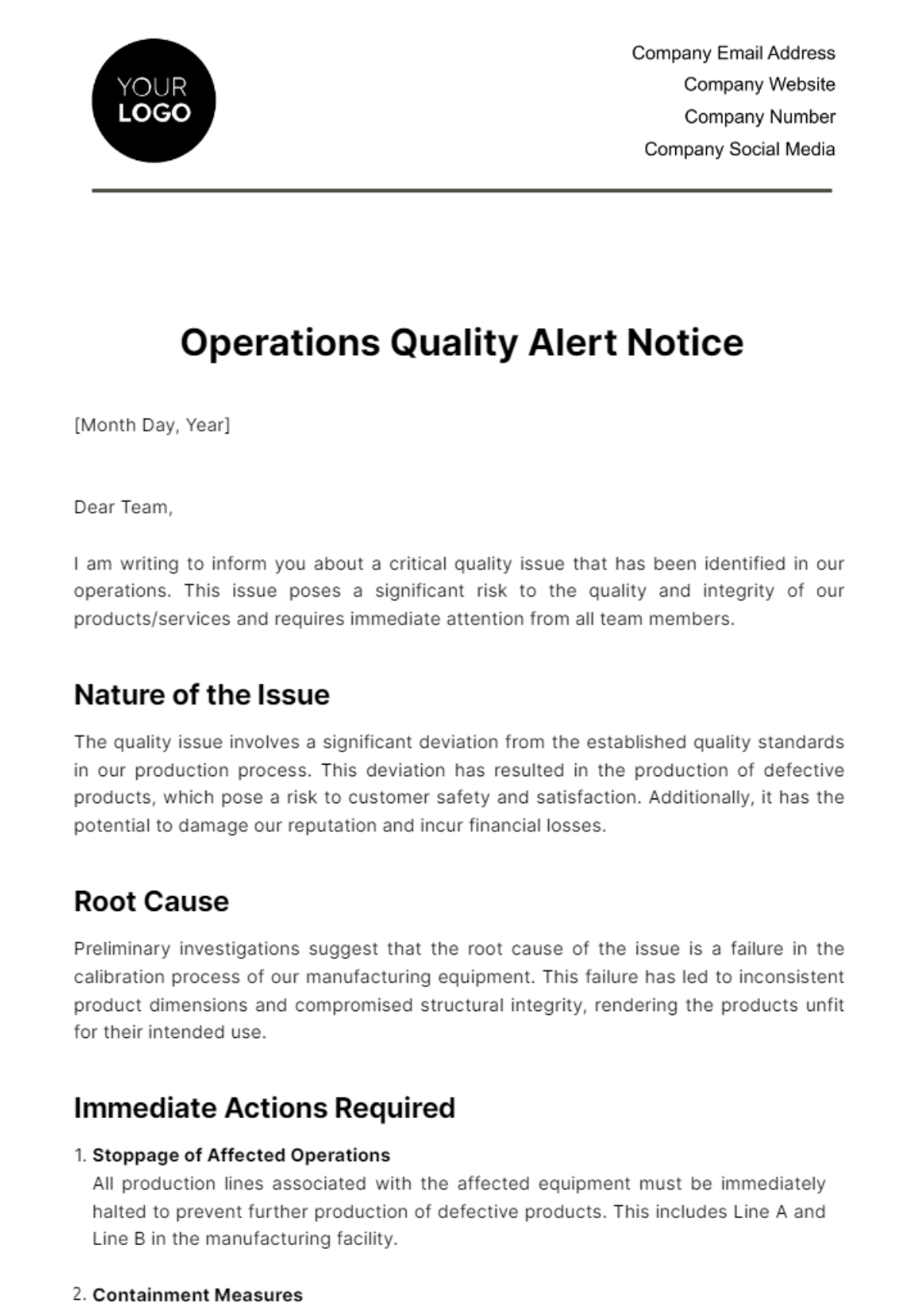

Free Operations Quality Alert Notice Template Edit Online & Download

Quality Alert Sample1

Parts Need To Be Neatly Stacked In The Cartons To Help Prevent Deformation.

When Not Stacked Properly, Parts Can Get Deformed And Cause Assembly Issues At Our Customer’s Facility.

Rules I Adhere To Include Keeping The Quality Alert To A Single Page, And Giving Ownership To Supervisors Out On The Floor By Giving Them The Authorization To Cancel A Quality Alert At Any Time.

When A Problem Is Identified We Investigate,And Post (And Update) The Quality Alert At The Work Cells On The Production Floor.

Related Post: